The general rule of bevels is to never grind one before wrapping it. They are machine made and the edges are smooth and perfectly even allowing for the foil to adhere securely. We never grind a bevel because they can chip and thus ruin the beveled effect with distracting glints of light poking out around the ground edge.

That said, there's an exception to EVERY rule. Occasionally a bevel border will be slightly short in which case you must space the bevels out to fill the distance. Then there are times when the bevels are too long to fit the subject matter. Your only option at this point is to break the rule and grind your bevel(s). Of course there's a correct way to do this and an incorrect way. We're going to show you both and then tell you what you SHOULD do.

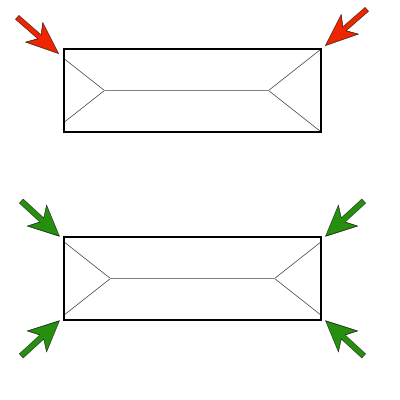

Below is a diagram of your standard stock (pre-made shape) bevel. The red arrows point to an enlarged corner and shows you how the tapered edge comes out perfectly to the corner.

First off, if you have to grind a bevel use a dull grinding wheel! This will prevent your bevel from chipping. In the example below you can see that 1/4 of an inch has been ground from the left side of the bevel. The left red arrow shows how the tapered edge no longer meets the corner as it does on the right side of the bevel. This lack of symmetry is very obvious and very distracting. We can't avoid having the tapper missing the corner but we CAN make it less obvious by grinding both sides of the bevel. Instead of grinding 1/4 of an inch away on one side we can take half of that (1/8 of an inch) and take it off of both sides. The green arrows point to this solution. The bevel itself remains symmetrical and the amount of mismatch is far less noticeable.

I would place this ground bevel in the center of the border to help keep the string of bevels symmetrical. There is actually another way to handle this problem as well. Instead of taking 1/4 of an inch off of a single bevel you can take 1/16 off both sides of of two different bevels. The mismatched taper to the corners would be extremely negligible this way. The only 'problem' with this method is that the more bevels you grind, the greater the odds are that one or more bevels will chip. For that reason it's always good to have a dull grinder wheel on hand that you can switch over to while grinding any bevels that need to be adjusted.Paul

No comments:

Post a Comment